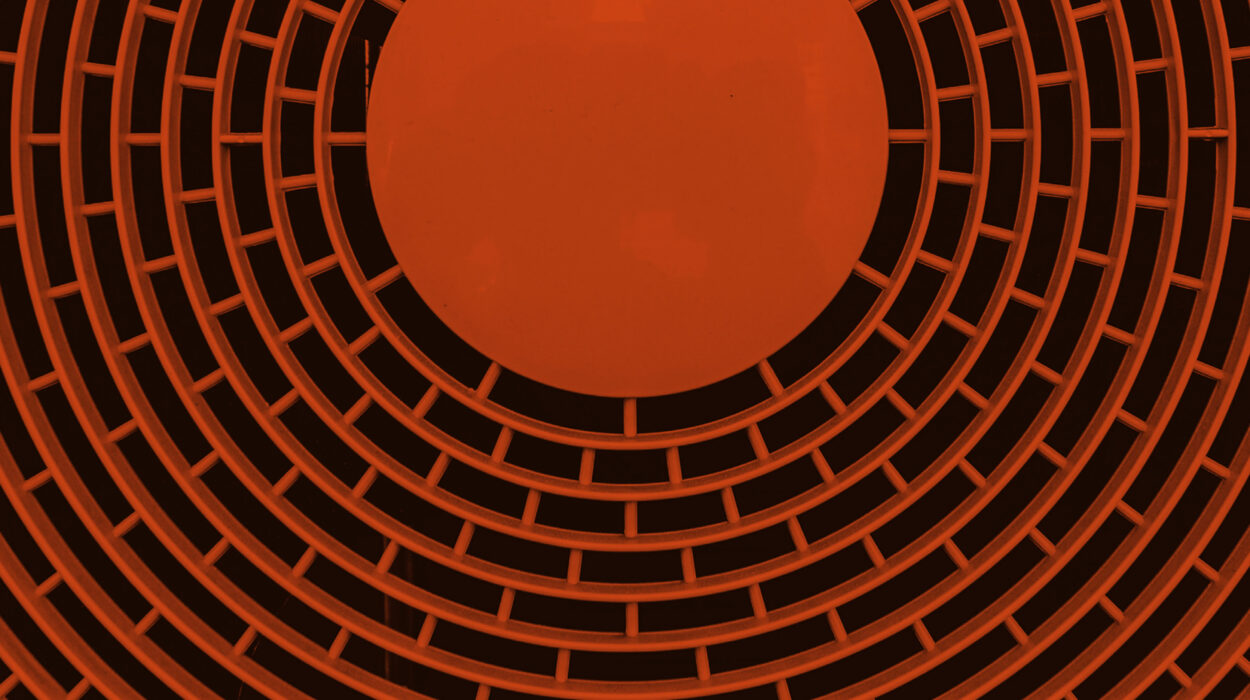

Booster Set Replacement Project

Our customers had three booster sets that were at end of life expectancy and had obsolete parts.

Our customers had three booster sets that were at end of life expectancy and had obsolete parts.

With the additional demands for fresh air this particular client of Pumptec’s had increased the hours and capacity of operation of their fresh air circulation system.

An extreme weather event caused the contamination of the critical pump circulation fluid in an automotive supply chain manufacturer.

A call direct to Pumptec’s head office from a waste to energy plant led to us sourcing and fitting ‘unobtainable parts’.

The air handling units in a large commercial premises were approaching the end of their useful life.

The 11-storey building has recently undergone a major HVAC refurbishment and Pumptec Engineering were asked to provide a proposal for the project.

Following an ongoing concern with the vibration levels on the Primer Extract Fan, Pumptec were asked to confirm the problem initially.

At one of the main office buildings of a large financial institution, we were asked to survey the existing air handling units as the on-site maintenance team had noticed that the dampers were not operating properly.

The scope of works was to replace the old fan motors with new energy efficient motors over 5 weekends to minimise downtime as these units provided cooling and heating to critical areas.

Pumptec were recently asked to attend site to an international aerospace company to survey a badly vibrating fan assembly.