Mechanical Services

Our time served engineers provide support for a complete range of mechanical services, to save time and resources.

Equipment Overhauls

Save money

If you’re looking to save your organisation unnecessarily premature investment costs, we can help you extend the life of your equipment through inspection, testing and providing a full range of equipment overhaul services.

An overhaul consists of identifying the worn or under-performing components and replacing or repairing them, thus reconditioning your equipment to perform as good as new. As well as avoiding an unplanned investment in new equipment, equipment upgrades performed during the overhaul can often reduce running costs too.

Avoid breakdowns

The condition of your equipment can be identified through condition based monitoring (CBM), such as vibration analysis and thermography and other forms of CBM methods. This will enable maintenance to be planned in advance which will reduce inconvenience, prevent unexpected failures and avoid downtimes that could cause serious financial losses and devastating product delays.

Reduce downtime

At Pumptec Services Group, we’ll work with you to find a solution that minimises downtime. Through careful planning, we schedule work to limit the impact and inconvenience to your workforce, your customers and end users. Decommissioning and removal, reinstallation and recommissioning, as well as transportation to and from our Service Centre can all be provided if necessary. We can also provide advice regarding your CAPEX Programme.

A Greener Solution

Equipment and asset upgrades to the latest technology can save energy and improve efficiency, enabling you to reduce your impact on the environment and reduce your carbon footprint.

Overhaul Processes

The Pumptec Services Group team are experienced engineers, who have developed a thorough equipment overhaul process, as shown below:

- Dismantle equipment and record relevant data.

- Clean and inspect components for wear.

- Identify and diagnose the extent of repairs and refurbishment.

- Produce engineering report and rectification quotation.

- Purchase OEM spares where appropriate and conduct repairs.

- Perform hydrostatic testing where appropriate.

- Reassemble, including repainting to required specifications.

- Make final quality checks.

- Dispatch to the customer for installation.

As suggested by our group company name, we are experts in all types of pump overhauls.

Typical parts that wear and will need replacing include o-rings, seals, bearings and impellers. These can either be replaced with original equipment manufacturer (OEM) parts or can be reverse engineered on older equipment where parts have been discontinued.

Below is a list of the most common pump types we monitor, service and maintain:

- Air Operated Diaphragm (AOD) Pumps

- Borehole Pumps

- Centrifugal Pump

- Chilled Water Pumps

- Cold Water Booster Pumps

- End Suction Pumps

- Fire Pumps

- Long & Short Couple Pumps

- Low Temperature Hot Water (LTHW) Pumps

- Multistage Pumps

- Positive Displacement Pumps

- Split Case Centrifugal Pumps

- Submersible – Foul & Surface Water

- Vacuum Pumps

In order to provide a complete service, as part of an industrial or HVAC project, we are able to provide electric motor overhauls.

Following the initial equipment inspection, worn or defective parts and components can be diagnosed then repaired or replaced. Bearing replacements are the most common service featured on motor overhauls.

We can overhaul a full range of motors, including the following:

- AC & DC electric motors

- Brake motors

- Gear motors

- Hoist motors

- Permanent magnet motors

- Special purpose motors

- Spindle motors

- Synchronous motors

Please contact us to discuss any of your equipment that isn’t performing as it should.

New Equipment Procurement and Spare Parts

Choose the right partner

Due to varying brands and the potential changes in availability of equipment in the industry, it’s important that your chosen procurement partner has access to a sufficient range of supply chains to provide the right solutions for your needs. Due to being well-established in the industry, we’ll identify the equipment and spare parts available on the market that will provide the best solution for you. And, because of our buying power and long-standing supplier relationships, we can attain them as quickly as possible, with favourable terms.

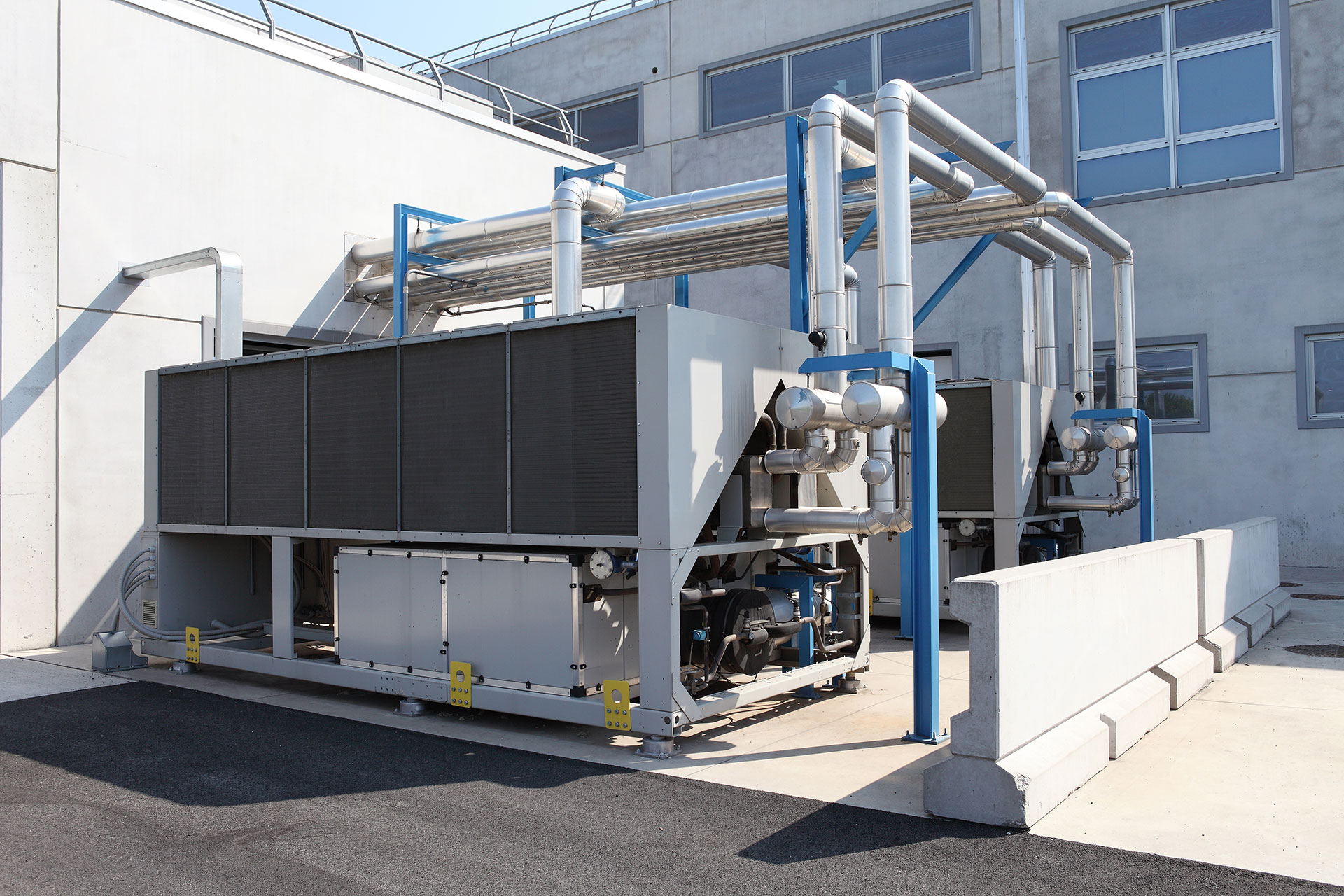

Renewing equipment and components

Replacing underperforming older equipment that’s beyond economical repair with newer, more technically advanced equipment can save a considerable amount of money in energy costs, not to mention increased reliability and consequently a reduction in downtime. An important factor when downtime could cause your organisation several thousands of pounds per hour (or even per minute!) in lost revenue. Upgrading old equipment with new parts can achieve a similar result.

Using their skill and experience, our engineers will report the correct specification and options for your replacement equipment. Sometimes we find that equipment that’s been installed previously is no longer the right solution, especially if the demands on the equipment have changed. We can source the correct replacement pump, replacement motor, replacement industrial fan, or other rotating equipment, through our extensive supply network.

From decommissioning old equipment, through to the sourcing and installation of the new equipment, our group can deliver the whole package.

On older machinery, spares may not be readily available on some makes and models of equipment. Being an established independent engineering company in the market affords us the advantage of access to OEM’s, specialist part manufacturers and suppliers worldwide.

Many large scale projects that we undertake are related to both industrial and FM applications. These can involve a wide range of equipment and component replacement such as valves, expansion bellows, mechanical seals and cold water booster pumps. Maintenance and servicing will uncover any issues and protect your mechanical plant assets.

Make the most of your existing heating, ventilation and air conditioning assets through the installation of more energy-efficient fans, pumps and motors. Partial system replacement can ensure your systems continue to function and serve their purpose well through regular scheduled maintenance and equipment replacement, conducted over a period of time.

Please contact us for a quotation on your new equipment and spare parts needs.

Service Centre Capabilities

When the project type and time frame permits, your equipment repairs and maintenance will be carried out offsite in our service centre. It provides our team with access to specialist lifting equipment and a full range of engineering, testing, fabricating and manufacturing tools and machinery.

Our extensive service centre facilities enable our team to be as efficient as possible for you, whilst providing a central point for accepting parts deliveries.

In our service centre we have the following capabilities:

- Training Solutions

- Equipment cleaning facilities

- Diagnostics

- Storage for equipment and parts

- Machining

- Lifting

- Welding

- Painting

- Testing

- Shot blasting

Dependent upon the type of project, where possible, we undertake equipment overhauls at our Service Centre. This can often be more cost effective and achieve a quicker service time, due to our engineers having access to specialist testing and engineering equipment all at one location.

From cranes to lift and dismantle larger pieces of equipment to lathes, traditional engineering tools, painting equipment, welding equipment and a range of machinery you’d expect at an independent engineering workshop, our Service Centre has it all onsite. By delivering these services inhouse we have far greater control over the schedule of your project and can save you costs.

Please get in touch to find out whether your next project is suitable for completion at our Service Centre.

Onsite Services

Nationwide service

If you need repairs, maintenance or site surveys to be carried out at your premises, our group can facilitate that for you. Our engineers are able to travel throughout the UK to provide you with a full range of onsite services. When working with the Pumptec Services Group, you’ll benefit from having access to both industrial and HVAC engineers, who work together as one team to deliver the solution that adds the most value to your organisation.

We always aim to carry out repairs as close to the point of failure as possible. This minimises the risk to your business from equipment failure and downtime. Where the equipment needs a more in-depth overhaul or when it is assessed that our more specialist capabilities will be more appropriate, we will bring the item to our service centre.

Committed to safe working

Our engineers are fully health and safety trained as well as being experienced in operating in specialist environments, such as confined spaces and critical environments.

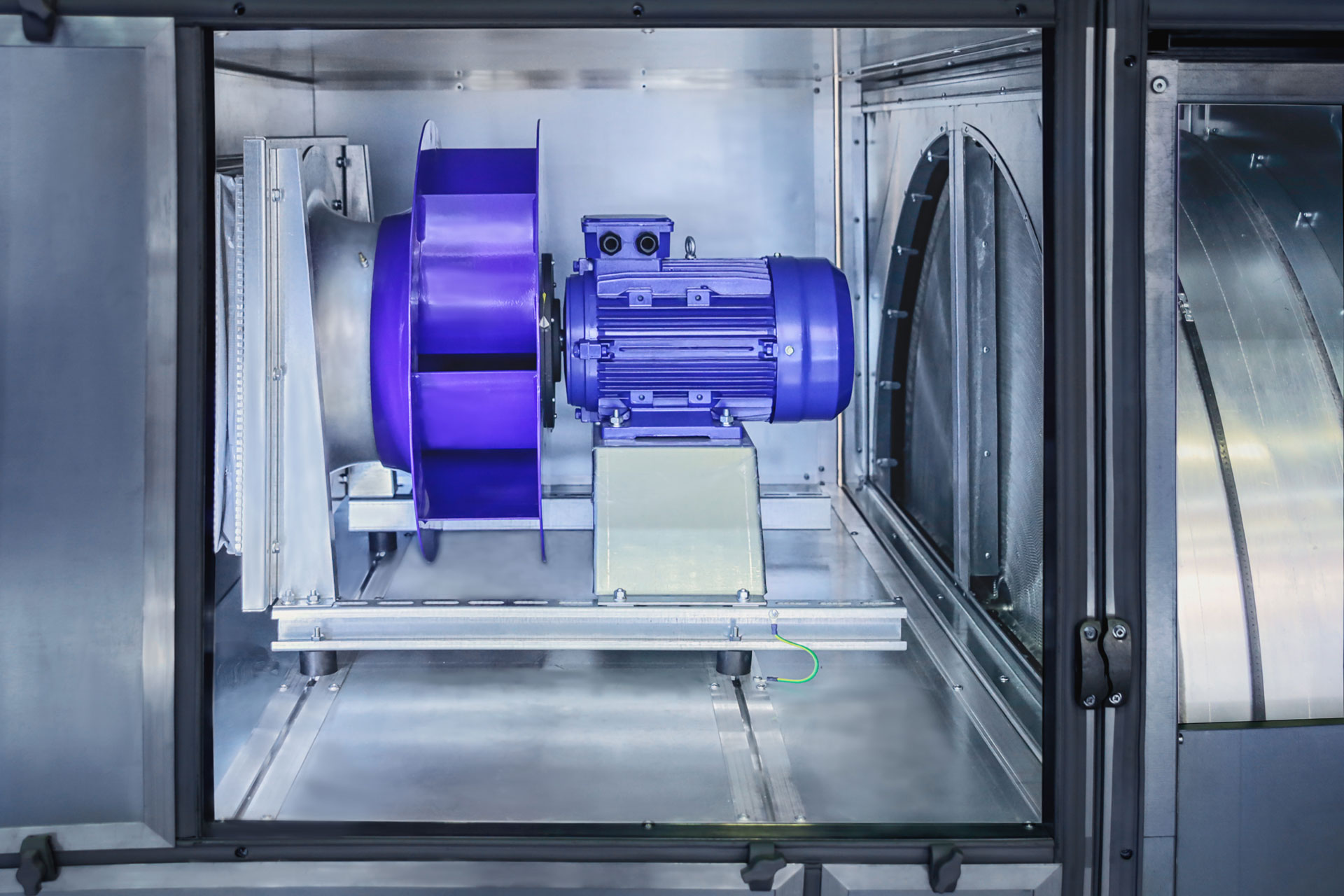

By overhauling your AHUs and fans, we can ensure your capital plant equipment continues to operate efficiently instead of falling into disrepair. Lack of planned maintenance can cause them to eventually fail completely and need to be replaced, at great expense.

Overhauls of your AHUs and fans minimises disruption, both to your organisation and your workforce. It can also avoid external associated costs, particularly when there are logistical issues and transport costs involved in delivering and positioning larger replacement units. Overhauls can improve equipment performance, workforce health and safety, as well leading to a reduction in running costs.

Typical work conducted during overhauls can include:

- Replacement or upgrade of filters

- Repair and repainting of corroded metalwork

- Add new pressure gauges

- Replace worn components such as bearings, fans, motors, anti-vibration mounts and flexible connections

- Repair or replace leaking heating or cooling coils

- Replace damaged or failed heat recovery devices

- Repair of replace control dampers and actuators

- Fix incorrect trapping to stop cooling coil drain pans from overflowing

We deal with all types of fans, across all manufacturers, including centrifugal, multivane, paddle, axial and bifurcated.

Over time, pipework can corrode, affecting the overall efficiency and performance of the system. Our engineers are able to plan, supply, replace and fit new pipework, as part of your industrial or FM project. This avoids additional workers having to be onsite, manages project costs more effectively and prevents delays in project completion.

We can also insulate pipework where required and repair existing pipe lagging, to maintain thermal or cooling performance.

Our fully skilled M&E engineers are trained and experienced in delivering a complete range of mechanical works and mechanical services involved with industrial and HVAC projects.

Whether involving PPM or new installations, our overall experience of building systems enables us to deliver the whole project with minimal disruption.

Our fully skilled M&E engineers are trained and experienced in delivering a complete range of mechanical works and mechanical services involved with industrial and HVAC projects.

Whether involving PPM or new installations, our overall experience of building systems enables us to deliver the whole project with minimal disruption.

Planned shutdowns are one of the areas where we can add a great deal of value to your engineering effort. We are able to provide time served, professional and fully equipped engineers to augment your engineering teams.

Prior to the shutdown we would confirm the scope of works, determine and order the spares required, and when appropriate provide pre-shutdown inspection reports to help you align the engineering priorities into the time available.

Our engineers are well versed to the demands of shutdown support and every task we complete for you comes with a full report for your engineering records.

To keep your systems and equipment running in the way in which they were originally intended, it’s essential that OEM parts are performing correctly. Through building good, long-standing relationships with our manufacturer partners, we’re able to gain information quickly, then provide you with outstanding support when faced with problems that less-experienced contractors may struggle to resolve. This may include warranty issues uncovered during industrial maintenance, cold room maintenance or PPM.

As an essential component, keeping your coils in good working order will extend the life of your assets. As part of our maintenance services on your systems we can service, repair and replace a wide range of coils found in industrial radiators, water and dry air coolers, heater batteries, water chillers and evaporators – to name just a few. The types of coils we can service and replace typically include fan coils, frost coils, DX coils, fin coils and condenser coils.

The reliability of cooling systems and heating systems is key to keeping your workforce and customers comfortable, at times when the British weather is doing its worst. In critical environments and places where air quality or temperature needs to be carefully controlled, it becomes less about comfort and is instead an essential part of your business. System failure could then mean serious financial losses or health and safety risks for your organisation.

Through our specialist division, we are a leading provider of HVAC repairs and HVAC maintenance. There are a number of key areas within your heating, ventilation and air conditioning system that need to be regularly maintained to keep it functioning exactly as it should. Our engineers will ensure your air returns, filters, exhaust outlets, ducts, electrical components, fans, compressors, coils and blowers are all performing well.

Our team are specialists in performing repairs that are time critical and can respond to reactive breakdowns, as well as offering full support on planned maintenance projects. Whatever your HVAC requirements, we’ll work with you to find the best solution.

We can repair, service, maintain and replace cold water booster units. Cold water booster units should be serviced annually. Improper or infrequent maintenance of booster sets can invalidate insurance and present health and safety risks for clients and employees. If a cold water booster unit fails, it will prevent critical systems from functioning, resulting in a temporary shutdown in your operations.

Valves are often an essential part of an industrial or HVAC plant. Our team is fully experienced in replacing valves as part of larger projects. As well as replacing them onsite, we will identify and procure the right valve so we can deliver you the whole solution, saving you time and hassle.

Expansion bellows must be installed correctly within your pipe system, in the right location, to ensure that critical environments don’t suffer from unexpected and costly problems at a later date. Not only can we install expansion bellows as part of a project, we can supply them too.

Pressure systems require regular inspections in order to identify problems such as damaged parts, corrosion, leaks and a reduction in system performance. Our engineers will identify any worn or failing parts and replace them, which may include filters, fittings, flow switches, sensors, pumps, penetrators, pressure gauges, valves and seals.

Our experience enables us to work quickly and work with you to minimise downtime and limit any inconvenience caused to operations and your workforce.

Get in touch to discuss your onsite service requirements.