HVAC Technical Support and Projects

Our inhouse skills and expertise enables us to provide you with the correct support, maintenance and advice for your HVAC systems.

Technical Support

Setaria Group’s team of experts provide 24/7 technical support to their varied client base across the UK.

Providing maintenance solutions advice to enable our customers to remain compliant and in line with best industry standards and practices such as SFG20.

Our team of experts also provide over the phone advice for customers who are experiencing issues with their plant, helping them remotely to fix onsite issues for various aspects of M&E critical plant failure.

We also provide our customers with the required asset classification maintenance frequencies and advise them on what the statutory law is for various aspect of plant maintenance and procedures.

This helps asset management and allows longevity of equipment with a maintenance program in line with best practice.

Forward maintenance regimes and future CAPEX spend is also a service that Setaria Group can provide support on for mobilisation projects for specific contracts.

These are constructed in line with CIBSE guidelines, environment and criticality of equipment to enable our customers to make an informed decision on what is best for them for their own specific maintenance requirements.

Projects

Setaria Group has extensive experience in supporting our customers’ asset replacement or CAPEX schemes.

This is also supported via our long relationships with various OEM’s, which enables us to provide the latest available technological advances across various aspects of plant replacement.

Once a product selection for a project has been implemented we also deliver time-critical works to ensure minimal or no disruption to our client’s operational teams and business.

Projects delivered in line with CDM regulations, statutory compliance, and health & safety procedures.

We can also provide commissioning services for all new plants and equipment, plus carry out validation surveys of existing plants where original commissioning data is not present.

We can also carry out a full dilapidation report on your plant and equipment to collate a full list of plant details and a full condition report of existing equipment to allow customers to make an informed decision on the plant to be replaced or overhauled.

Some examples of typical asset replacement projects are below:

- Chiller replacement.

- Air Conditioning replacement or installation and design.

- Pressure system replacement – Cold Water Booster Sets and Pressurisation Units.

- AHU overhauls and replacement.

- Cold Room asset replacement.

- System validation and commissioning.

Make the most of your existing heating, ventilation and air conditioning assets through the installation of more energy-efficient fans, pumps and motors. Partial system replacement can ensure your systems continue to function and serve their purpose well through regular scheduled maintenance and equipment replacement, conducted over a period of time.

Please contact us for a quotation on your new equipment and spare parts needs.

Onsite Services

Nationwide service

If you need repairs, maintenance or site surveys to be carried out at your premises, our group can facilitate that for you. Our engineers are able to travel throughout the UK to provide you with a full range of onsite services. When working with the Pumptec Services Group, you’ll benefit from having access to both industrial and HVAC engineers, who work together as one team to deliver the solution that adds the most value to your organisation.

We always aim to carry out repairs as close to the point of failure as possible. This minimises the risk to your business from equipment failure and downtime. Where the equipment needs a more in-depth overhaul or when it is assessed that our more specialist capabilities will be more appropriate, we will bring the item to our service centre.

Committed to safe working

Our engineers are fully health and safety trained as well as being experienced in operating in specialist environments, such as confined spaces and critical environments.

By overhauling your AHUs and fans, we can ensure your capital plant equipment continues to operate efficiently instead of falling into disrepair. Lack of planned maintenance can cause them to eventually fail completely and need to be replaced, at great expense.

Overhauls of your AHUs and fans minimises disruption, both to your organisation and your workforce. It can also avoid external associated costs, particularly when there are logistical issues and transport costs involved in delivering and positioning larger replacement units. Overhauls can improve equipment performance, workforce health and safety, as well leading to a reduction in running costs.

Typical work conducted during overhauls can include:

- Replacement or upgrade of filters

- Repair and repainting of corroded metalwork

- Add new pressure gauges

- Replace worn components such as bearings, fans, motors, anti-vibration mounts and flexible connections

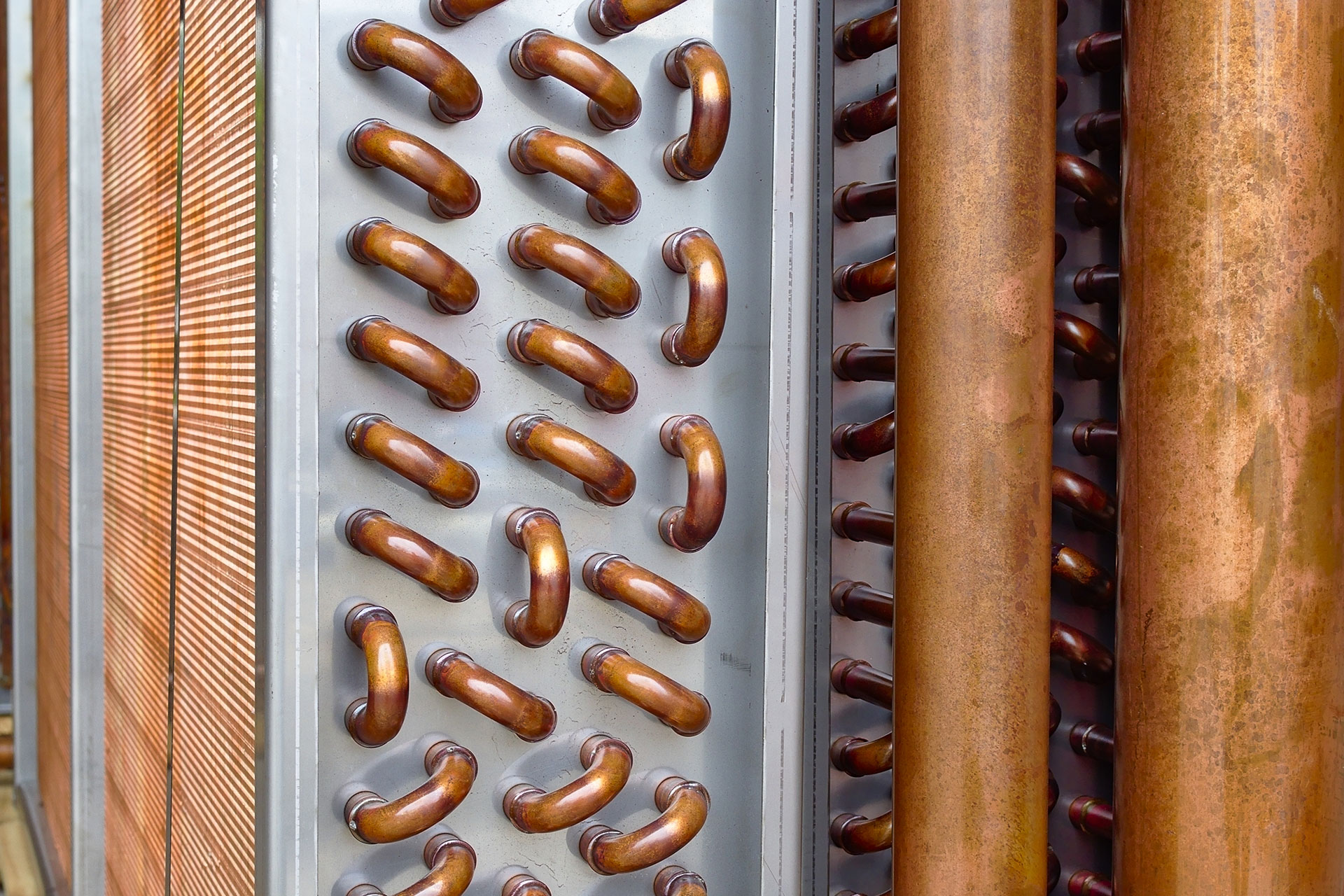

- Repair or replace leaking heating or cooling coils

- Replace damaged or failed heat recovery devices

- Repair of replace control dampers and actuators

- Fix incorrect trapping to stop cooling coil drain pans from overflowing

We deal with all types of fans, across all manufacturers, including centrifugal, multivane, paddle, axial and bifurcated.

To keep your systems and equipment running in the way in which they were originally intended, it’s essential that OEM parts are performing correctly. Through building good, long-standing relationships with our manufacturer partners, we’re able to gain information quickly, then provide you with outstanding support when faced with problems that less-experienced contractors may struggle to resolve. This may include warranty issues uncovered during industrial maintenance, cold room maintenance or PPM.

The reliability of cooling systems and heating systems is key to keeping your workforce and customers comfortable, at times when the British weather is doing its worst. In critical environments and places where air quality or temperature needs to be carefully controlled, it becomes less about comfort and is instead an essential part of your business. System failure could then mean serious financial losses or health and safety risks for your organisation.

Through our specialist division, we are a leading provider of HVAC repairs and HVAC maintenance. There are a number of key areas within your heating, ventilation and air conditioning system that need to be regularly maintained to keep it functioning exactly as it should. Our engineers will ensure your air returns, filters, exhaust outlets, ducts, electrical components, fans, compressors, coils and blowers are all performing well.

Our team are specialists in performing repairs that are time critical and can respond to reactive breakdowns, as well as offering full support on planned maintenance projects. Whatever your HVAC requirements, we’ll work with you to find the best solution.

We can repair, service, maintain and replace cold water booster units. Cold water booster units should be serviced annually. Improper or infrequent maintenance of booster sets can invalidate insurance and present health and safety risks for clients and employees. If a cold water booster unit fails, it will prevent critical systems from functioning, resulting in a temporary shutdown in your operations.

We are experienced in the design and installation of a range of commercial refrigeration solutions, such, from chilled storage and cold rooms to refrigeration plants.

Improper or infrequent maintenance on commercial refrigeration equipment can lead to blockages, water leaks and eventually breakdowns. Over time, condensers can become blocked, resulting in reduced efficiency and increased operational costs. Planned preventative maintenance (PPM) can extend the life of your refrigeration units and can be conducted onsite by our engineers.

Poorly maintained chiller equipment will almost certainly increase electricity usage, which will increase your running costs, in addition to not being environmentally friendly.

An incomplete or absent servicing record can also lead to your manufacturer warranty becoming invalid, as this information is usually requested during warranty claims to check the equipment is being maintained to the required standard.

For all major brands of chillers and cooling equipment, we can provide you with a planned programme of both routine and specialist maintenance to maximise running efficiency and to extend equipment life span.

Particularly important within critical environments, Setaria Group, our specialist division within the Pumptec Services Group will ensure your air conditioning systems continue to run 24/7 as efficiently and effectively as possible. Our team of engineers are experts in the servicing and maintenance of all commercial and public sector and local authority air conditioning systems.

Over time your air conditioning equipment parts and components will begin to wear, causing leaks. To be F Gas compliant, your air conditioning and refrigeration plant must be leak free. An air conditioning fault will result in an increase in running costs, as well as the system becoming less effective.

Through regular servicing and planned preventative maintenance we’ll ensure your air conditioning systems are kept in optimal condition, whilst extending the life cycle of your equipment. In addition to consumables replacements, during maintenance work, we’ll identify upgrades for fans and controls where appropriate, which will significantly reduce energy costs for your company and reduce your carbon footprint.

Although air source heat pumps are generally low maintenance, there are a number of consumables and components that need checking and replacing every few years to ensure it continues to operate efficiently and reliably. During a typical service our engineers will check the valves, filters, system refrigerant and test for any electrical faults. The system pressure and temperature will also be checked to ensure the system is operating in the best way possible. If not checked for a while, it’s likely the evaporator and air inlet grill may need checking they are free from debris.

Pressure systems require regular inspections in order to identify problems such as damaged parts, corrosion, leaks and a reduction in system performance. Our engineers will identify any worn or failing parts and replace them, which may include filters, fittings, flow switches, sensors, pumps, penetrators, pressure gauges, valves and seals.

Our experience enables us to work quickly and work with you to minimise downtime and limit any inconvenience caused to operations and your workforce.

If the performance of your HVAC system has reduced, whilst your energy costs have increased, we can help. Intermittent technical issues can soon lead to complete breakdowns, which in critical environments can cause disaster and damage to expensive equipment.

Within our Setaria Group division, our team is on hand to address your HVAC technical issues. Our engineers are experienced in delivering HVAC support and consulting services for a range of industry sectors and FM projects. With access to OEM parts our reliable full time employed engineers and HVAC consultants are available UK wide.

Some examples of sectors we’ve delivered HVAC support and consulting for include: automotive, facilities management, manufacturing plants, retail, commercial, education, pharmaceutical, food processing, public sector, local authority, health sector, aerospace, finance and banking.

Get in touch to discuss your onsite service requirements.