Industry:

Aviation

Location:

Cheshire

Project:

Thermal Imaging diagnosis and repair

Summary

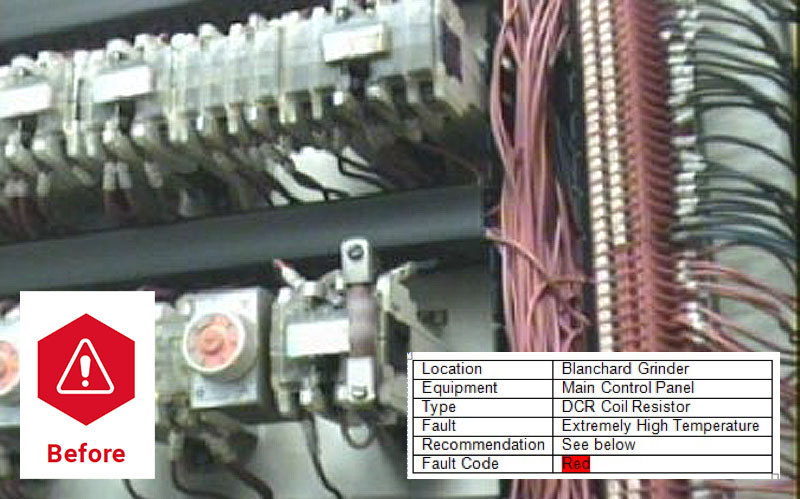

Pumptec were requested to carry out a thermal imaging survey to evaluate the risk of Fire at this purpose-built manufacturing and service facility.

As a manufacturer of high quality reciprocating compressor components, almost every electrical panel is critical in the process of the manufacture of high precision parts.

Issue

When the panel to one of the grinders was opened, the smell of high electrical heat was apparent.

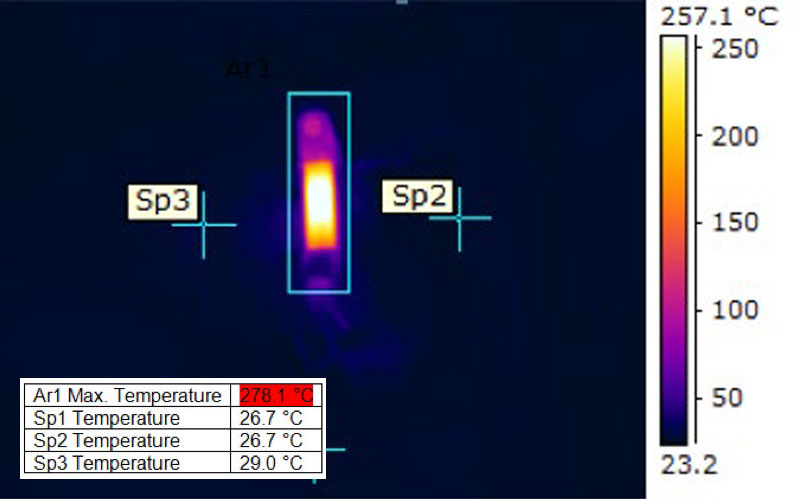

With the use of Pumptec’s Flir P65 Thermal Imaging camera, a full live scan of the panel was carried out. The camera highlighted a DCR Coil Resistor at a temperature of 278.1 degrees celcius.

What we did

The decision was made there and then to end the current production cycle, transfer to the opposite line and power down the panel. Once cooled sufficiently the resistor was replaced and the line re-started.

Had the resistor completely burnt out without prior warning the grinder would have stopped mid cycle, resulting in the scrappage of parts costing in the region of £35,000.

The remainder of the survey picked up numerous advisories that were able to be planned in for the following weekend whilst production was not running.

Key Challenges: Working in a live environment, fast track design and construction period.

Outcomes

Key Deliverables: Created a high quality and efficient system with a major return in investment.