Industry:

Automotive

Project:

Quarterly Routine VA

Problem:

Critical fault found on ASH main motor

Summary

As a preferred supplier to an automotive client, Pumptec carried out a vibration analysis program to monitor the condition of all the critical pumps, fans and drives within the Paint department in plant one.

Issue

On analysis, during April 2017, it was found that the main motor on the ASH extracting from the Basecoat Booth was indicating a clear defect on the motor drive end bearing at such a level that concerns were reported.

What we did

On Pumptec’s advice and with our assistance, a spare motor was located and taken to the Penthouse area ready for installation.

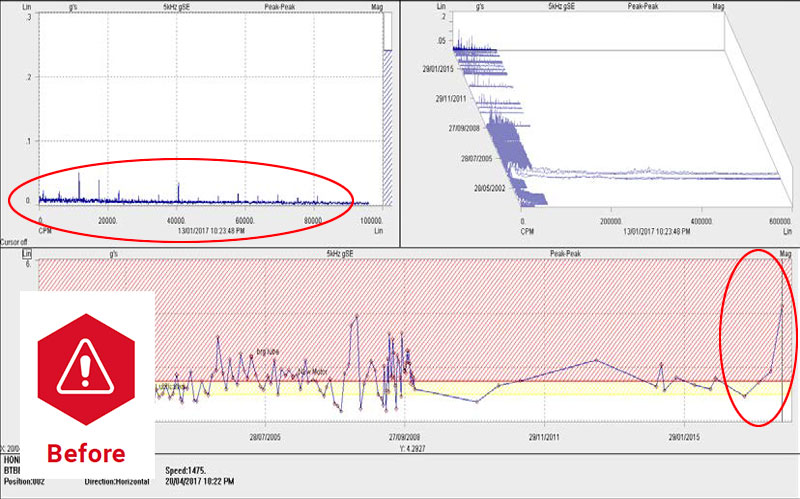

The image below shows the spectral data and trend data on the unit and a clear failure curve can be seen. To the human ear the defect was undetectable but the VA equipment converts the ultrasonic frequencies into the signature displayed.

Had this have failed completely, then production would have been unable to continue at a cost of approximately £1.5K per minute.

Outcomes

Key Deliverables: With a minimum replacement time of 2 hours, assuming all lifting gear is in place, this saved them in the region of £180K minimum, should a catastrophic failure have occurred. The motor was replaced and Pumptec will carry out further checks to confirm that all energy levels are within satisfactory limits.

Spike energy increase and on failure curve (bottom right). Non-synchronous spectral spikes indicating clear bearing defect (top left).